Store Location

Choose Your Store

You are currently in the Australian store. If you are located in New Zealand please select the correct store below.

You are currently in the Australian store. If you are located in New Zealand please select the correct store below.

The ProteX X-ray series can operate specifically for you to identify food contaminants like plastic, metal, bone, and glass, in addition to determining missing components, misshaped products and also many more innovative and advanced features

3 model options are available

AD-4991-2510

AD-4991-2515

AD-4991-3530

Please see the brochure for detailed specification and differences between models, or reach out to our customers solutions team and we can help!

The ProteX X-ray inspection system for food processers offers product inspection functions that can not be achieved by metal detection or checkweighing.

In situations when the total weight of a product is within tolerance, X-ray can be utilized to visually check as well as reject a product if there is missing out on product inside the product package.

X-ray can be utilized to discover inconsistencies and variances in products that need to be rejected, like damaged or imperfect products.

In circumstances where the product changes in the course of the production process, it might be necessary to examine the seal of the product.

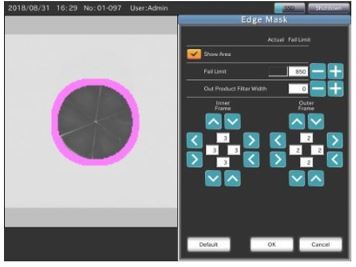

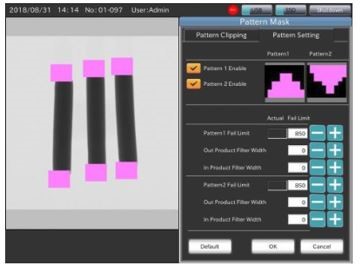

Products with clips as well as oxygen absorbers can be masked to look for presence and also prevent a false detection.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below